Facilities

The Boston University Vacuum Calibration and Testing Facility

The BU VACTEF, whose construction was funded by Boston University, was designed initially to support a NASA-sponsored sounding rocket program. It consists of a long, clean vacuum chamber with an optical – UV collimator at one end. The chamber was sized to permit the inclusion of a complete sounding rocket payload viewing a 1 arc sec point source via an internal collimator. Designed for vacuum UV absolute flux and angular resolution calibration, it can be also used for measurements of scattered light and baffling, grating sensitivity and blaze, reflective and transmissive efficiency of optics, etc.

Figure 1: VACTEF vacuum tank in room B17 of the CAS building at Boston University. Three cryopumps are seen at the top with blue labels, payload is inserted through large vacuum door at the left end, and collimator is at the far right end.

The facility is housed in a differentially-pumped, dual-chamber vacuum system whose interior has been brought to a high mechanical polish and cleaned for ultrahigh vacuum to minimize gas loading The chamber where instrument calibration occurs is 5 meters long and 3/4 meter in diameter and is fabricated from No. 304L stainless steel. This chamber is roughed with a scroll pump and evacuated to ultra-high vacuum with three cryogenic pumps. None of these pumps contain any oil in their vacuum vessels, ensuring hydrocarbon-free conditions. This is crucial in eliminating the possibility of contamination of any UV instrument. Any hydrocarbons contaminating the instrument would polymerize on its optical surfaces when exposed to light, and degrade the reflectivity of these surfaces to ultraviolet light. The empty chamber can go from atmospheric pressure to 5 x 10-8 torr in twenty-four hours, and should reach a base pressure in the mid 10-9 torr region after about a week. Three quartz lamp arrays are housed in the chamber to provide bake out, if desired.

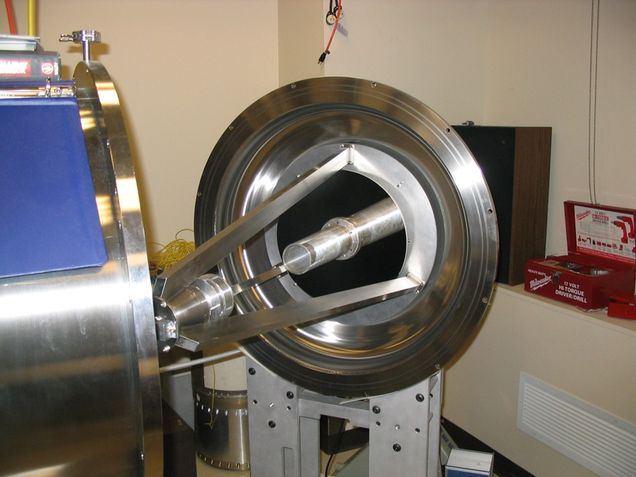

The chamber contains a 37 cm diameter ultraviolet collimator based on a Dall-Kirkham telescope which is always used on axis to minimize coma. The optics for this collimator are fabricated from Cer-Vit, a low expansion glass, which has been overcoated with Al/MgF2 to provide good reflectivity far into the ultraviolet region of the spectrum. The image quality of the collimator is better than 1 arcsec., and the chamber’s subframe is damped to ensure vibrations will not be transmitted to the optics.

Figure 2: View of collimator telescope inside chamber, looking toward the primary mirror. The image quality at UV wavelengths is 1 arc sec.

The light source is housed in a separate chamber, and consists of a windowless gas-discharge cell—with the type gas chosen by the user—and several commercially-made discharge lamps. The latter include a deuterium lamp, a cadmium lamp, a mercury lamp, and several aging platinum-neon lamps surplus from the Hubble Space Telescope’s calibration process. (As they age, platinum-neon lamps release hydrogen, thus making them a useful source of H Ly a). Detection facilities include a photomultiplier tube with a KBr photocathode calibrated absolutely, and a NIST-calibrated photodiode with a useful wavelength range of 50 through 122 nm.

Figure 3: Mounting structure for light sources at focus of collimator. Using a gate valve, light sources can be switched without disturbing the high vacuum in the main chamber.