From Sheila Russo’s lab, a soft robotic tool to help detect lung cancer early, when it’s most curable

By Patrick L. Kennedy

Imagine standing outside a hedge maze and shoving a garden hose into it. Now, holding one end of the hose in your hands, you’re trying to maneuver the other end of the hose in order to hook an unseen ribbon that’s stuck on a little branch deep within the shrubbery. Oh, and even though you know roughly where the ribbon is, a strong gust of wind periodically blows through the bushes, moving all the branches out of place.

If you can see how the physics are against you here, then you understand the task facing pulmonologists as they seek a biopsy of a lung cancer nodule using a conventional bronchoscope, says Assistant Professor Sheila Russo (ME, MSE).

“Meanwhile, people continue to die,” Russo says. “This is what keeps me and my colleagues motivated to come into the lab in the morning. We’re engineering soft robotic solutions to this societal problem in healthcare.”

Lung cancer is the deadliest form of cancer worldwide, partly due to the difficulty in catching the disease at its earliest stage, when it is most curable, says Russo. The lungs are a complex pair of organs, with the trachea branching out into a maze of smaller and smaller airways and ducts. Most cancerous lesions develop in those tiny ducts, way out in the periphery of the lung.

The location of a possible tumor nodule might be identified by a CT scan, but in order to extract a biopsy, a clinician needs to thread a bronchoscope into the lung’s periphery, find the tumor and puncture it, as in the Sisyphean scenario with the hose conjured above. Meanwhile, the patient’s breathing motion makes the nodule a moving target. As a result, lung tissue might be punctured in the wrong place, and patients will go home unclear that they even have a tumor.

Russo has a solution. With an interdisciplinary team combining expertise in mechanical engineering, materials science and engineering, biomedical engineering, and clinical medicine, she has developed a soft-robotic-assisted bronchoscope. With remote control, a pulmonologist can steer the business end of the scope and deploy the needle with accuracy from outside the patient. Published last year in Soft Robotics, the innovation recently earned Russo’s lab a prestigious National Institutes of Health (NIH) Research Project Grant (also known as an R01).

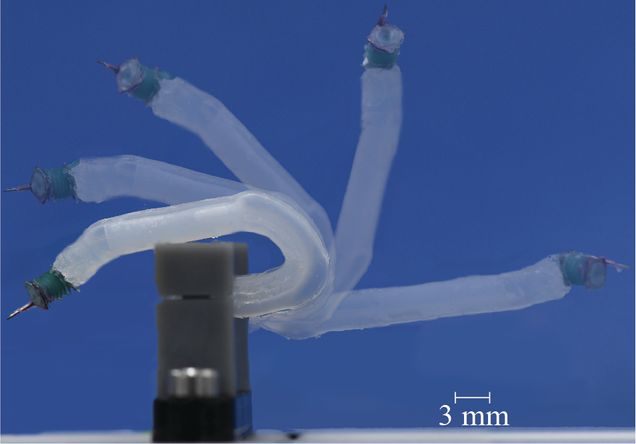

Whereas a traditional bronchoscope is six millimeters in diameter and has only 120 degrees of rotation, the Russo team’s robotic scope has a diameter of 2.4 millimeters and can rotate more than 180 degrees. Embedded with a camera as well as a needle, the device moves by means of three independent fluid pressure-driven actuators and uses a kind of airbag to stabilize itself in the moving airways, a bit like a subway rider grabbing a handrail. The device is made of soft materials that allow the tip to curl back onto itself.

“This allows you to navigate into very complex configurations within the lungs in very deep locations,” says Russo. “It’s a more precise, more accurate approach.”

Russo and her collaborators were able to miniaturize the scope by using new materials and even new fabrication processes to produce the robot. “We had to start from scratch and develop novel manufacturing technologies that enable us to scale these devices down as much as possible,” she explains.

Key to the development of the device has been the input of pulmonology experts such as Assistant Professor Ehab Billatos of the BU Chobanian & Avedisian School of Medicine.

“For us as robotics-assistant engineers,” says Russo, “we definitely want to have clinicians on the team who can tell us, ‘On a daily basis, this is my struggle. Can you engineer a robotic solution that can make my job easier, and at the end of the day, improve the health of my patients?’ So, we’re working at the interface between pulmonology, manufacturing, mechanical engineering, electrical engineering, controls, and software engineering. There’s really a variety of different skills that have to come together to be able to successfully work on this research.”

Ultimately, as the team further develops the technology with the NIH R01 grant, Russo hopes to simplify the control of the device with semiautomatic navigation, making it as easy as possible to train surgeons in its use.

“And that means you can bring good quality healthcare to remote areas,” says Russo. “We’re lucky here in Boston—we have the best hospitals. But I come from a very small rural town, and probably the best hospital my family and friends have is about two hours away. Imagine putting technology like this into the hands of clinicians there and in other areas in the country and the world, so everyone can have access to that level of high-quality healthcare that we all need.”

Image at top