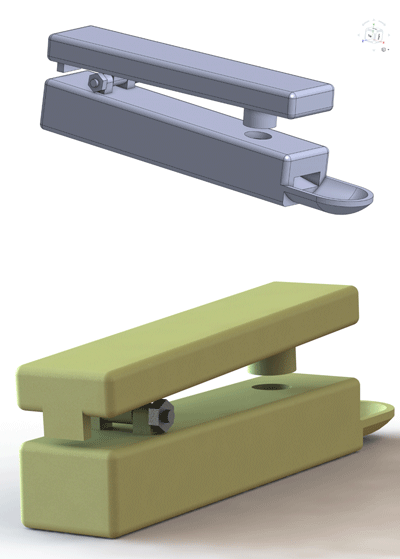

Karen Jacobs (right), Rebecca Khurshid (center), and Amy Aceto (’21) demonstrate a 3-D printed soda holder, designed to assist a person with arthritis. Sargent and engineering students collaborated on the design and production of the device. Photo by Jackie Ricciardi

For people with arthritis, everyday tasks like holding a can of soda or applying makeup can be painful—even impossible. Orthotics, easy-grip utensils, and other assistive devices can make life easier for those with physical limitations, but their one-size-fits-all approach and high cost can be prohibitive. Now, the rise of 3-D printing offers occupational therapy practitioners and their clients an alternative for creating inexpensive, customized devices.

It’s a technological approach that Karen Jacobs, a clinical professor of occupational therapy, is embracing. Jacobs’ office on the fifth floor of Sargent College is filled with vibrant mementos collected over a 40-year career in occupational therapy. Books on musculoskeletal disorders and ergonomics (including those she wrote) and myriad awards and commendations—many from the American Occupational Therapy Association where she served as president from 1998 to 2001—line her crowded bookshelves. Colorful snow globes, stuffed animals, and student artwork fill in the gaps. Among the many artifacts is a slightly newer mark of Jacobs’ innovative spirit: a sleek silver and blue 3-D printer. Given her focus on ergonomics, Jacobs has become a fan of the technology’s ability to have a positive impact on those who need help with activities of daily living.

“We are always looking for assistive technology, or adaptations,” says Jacobs. “The introduction of the 3-D printer allows us to better match what a person needs through the design of an individualized item.”

To connect her students’ therapeutic training with 3-D technology expertise, Jacobs had only to look across the street. She partnered with Rebecca Khurshid, an assistant professor of mechanical and systems engineering, to recruit engineering students for a four-week project. In fall 2018, Jacobs took the first-year doctor of occupational therapy students from her Analysis and Adaptation of Occupation course over to the College of Engineering, where the students from the two schools tackled a challenge: design an assistive device for a hypothetical client with a fine motor limitation like arthritis—and print it.

The occupational therapy students developed case studies and proposals. They then worked with the engineering students at two of BU’s maker spaces: the Engineering Product Innovation Center, which has twelve 3-D printers, and the Binoy K. Singh Imagineering Laboratory, which has two. At first, they experimented with drawings and Play-Doh models, before creating digital designs.

“We are always looking for assistive technology, or adaptations. The introduction of the 3-D printer allows us to better match what a person needs through the design of an individualized item.”

—Karen Jacobs

“A lot of the engineering students are looking to apply what they’ve learned in the classroom in a way that helps people,” says Khurshid, director of the Collaborative and Integrative Robotics Laboratory at BU’s Center for Autonomous and Robotic Systems. “This is especially true at BU, where the curriculum is designed to train societal engineers,” she says.

The printed devices created by the joint teams included a soda holder, mascara applicator, and PlayStation joystick extender. Sargent’s Laura Stursberg (’21) and her team designed an adaptation with a real client in mind—her 82-year-old grandmother Charlotte, whose arthritis made it hard for her to crochet, a longtime hobby that requires fine motor skills. An ergonomic crochet hook Stursberg ordered online made grasping the yarn easier, but the fit wasn’t quite right. With the help of Katherine Shannahan (ENG’20), the team printed a customized version. The one-inch-long adaptive device has two connected circular openings, one for Charlotte’s index finger and the other to guide the yarn.

“The device took care of the yarn so it took a bit of the bending of her hand out of the equation,” says Stursberg. While the prototype wasn’t perfect—the team realized they needed a way to control the tension of the yarn—the process is meant to be iterative. “The assistive technology process is basically ‘design—fabricate—test,’” she says.

Charlotte Dewley, the grandmother of Laura Stursberg (’21), crochets with the aid of a 3-D printed assistive device.

The World Health Organization reports that more than one billion people worldwide need an assistive product to help maintain or improve both function and independence. “Instead of going online and ordering a device, we can customize it, and at a reduced cost,” says Jacobs, who also directs Sargent’s online postprofessional doctor of occupational therapy program.

After the initial investment in a 3-D printer (which can cost between $500 and $2,500), materials are relatively inexpensive. “Most items are under $5,” says Jacobs of the final cost of a printed assistive device. And 3-D printers are becoming more ubiquitous, available at many universities and public libraries.

Other Sargent occupational therapy faculty members have also incorporated 3-D printing into their curriculum. In Lecturer Kevin Berner’s assistive technology class, students have printed adaptive buttons, which people with paralysis can use to activate keyboards, touchscreens, or responsive toys with their best available voluntary movement, such as their hand, elbow, or head. Such buttons might typically cost $65, but those printed by the class were about $8 each.

Even more valuable than the physical assistance is the psychosocial impact. “Giving someone the opportunity to engage in an activity independently can reduce their reliance on caregivers and provide a great deal of meaning in terms of self-sufficiency,” says Berner.

In fall 2019, Jacobs plans to assign every group a real client. And she’s envisioning ways to use 3-D printing throughout the semester, perhaps to custom-make devices for residents of a local retirement home.

Jacobs considers the project a success, bringing together problem solvers with different perspectives and expertise. It’s a model she’s using in her own work: she and Khurshid are collaborating with researchers at Hebrew SeniorLife, a senior care organization based in Boston, on the development of a smart walker that will use low-cost sensors to help prevent falls.

Most gratifying is the unique learning experience their collaboration created for the students. “It connected students across BU’s different colleges,” says Jacobs, “to have a better understanding of another profession they could work with in the future.” She recalls the students’ first meeting, when they were asked to explain their fields to each other. The first response: “As engineers, we solve problems.” The Sargent students laughed. “We do that too,” they said.